Optimize your grinding process via temperature control

Water injection is one way to control and maintain the cement temperature at mill outlet at a preset level.

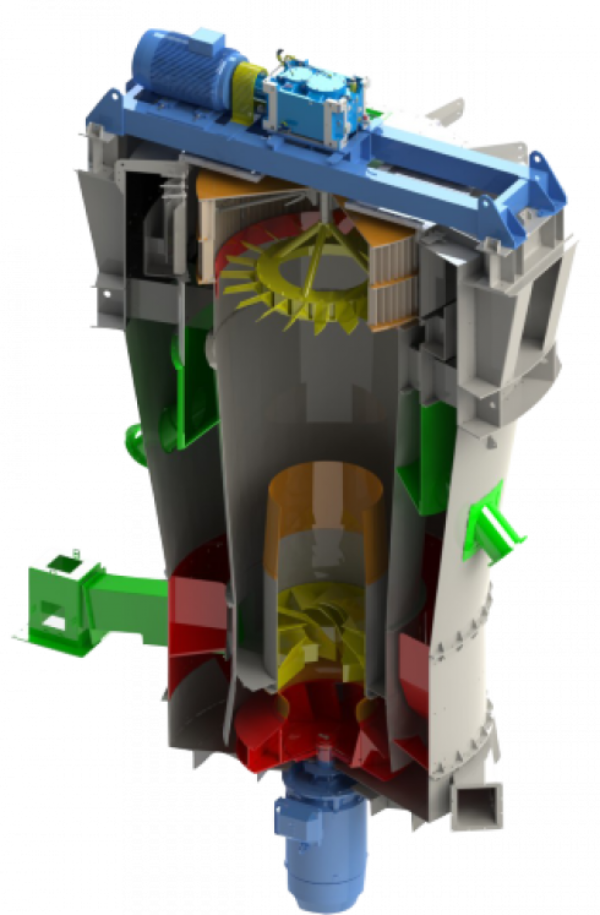

Depending on the circuit thermal balance analysis and the mill design, Magotteaux water injection system automatically sprays water into the mills in 3 different ways:

- 1st chamber via its inlet

- 2nd chamber via mill outlet or via mill inlet and intermediate diaphragm (mills with central driving shaft)

- Both chambers if need be for process reasons