Efficient & compact: what else?

The 4th generation dynamic classifier has been introduced to the cement world market by Magotteaux, in order to have a better compact and energy efficient solution for existing circuit revamping or closing.

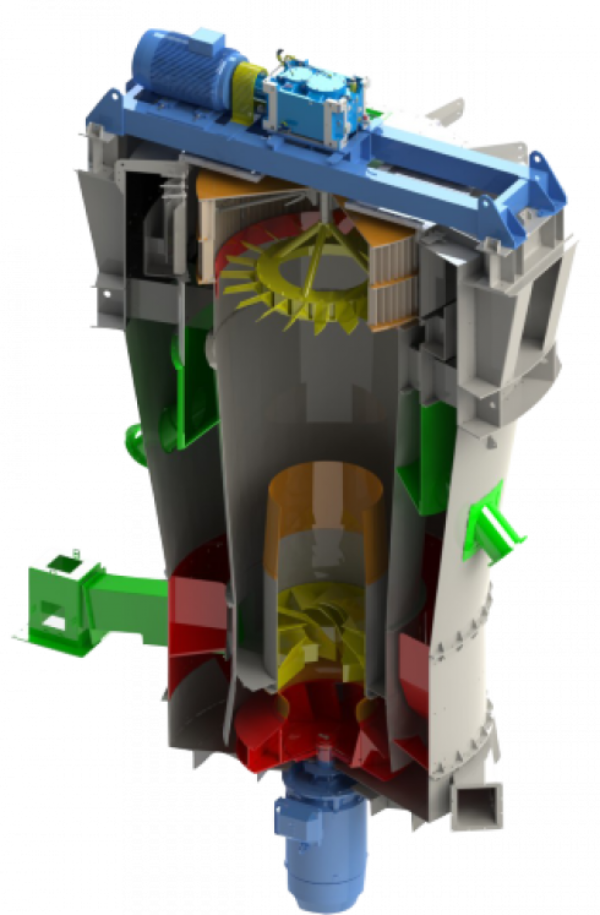

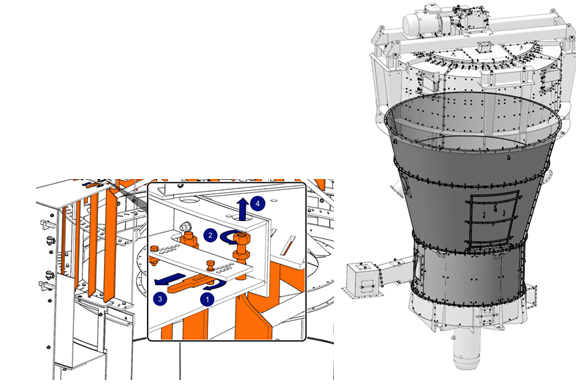

This ultimate classifier is now fitted with an integrated cyclone and recirculation fan inside its patented design body, a perfect combination between the compactness of a 1st generation and the efficiency of a 3rd generation classifier.

This is your perfect solution to upgrade cement/raw/slag/fly ash ball mill circuits or create new lines with limited footprint, when you have some of the following targets:

- Increase production

- Improve quality standard, clinker factor

- Reduce power consumption

- Reduce maintenance costs and ease maintenance operations in an “all in one” machine, thanks to wide access doors, high-level wear protection. This imperative was part of the MagoClass concept from first steps of its engineering

- Keep low the global initial investment as you avoid expensive building transformation costs, huge external process filter, fan & dedicated ducting

- Reduce installation/commissioning/downtimes

- Meet sales targets, gain new markets