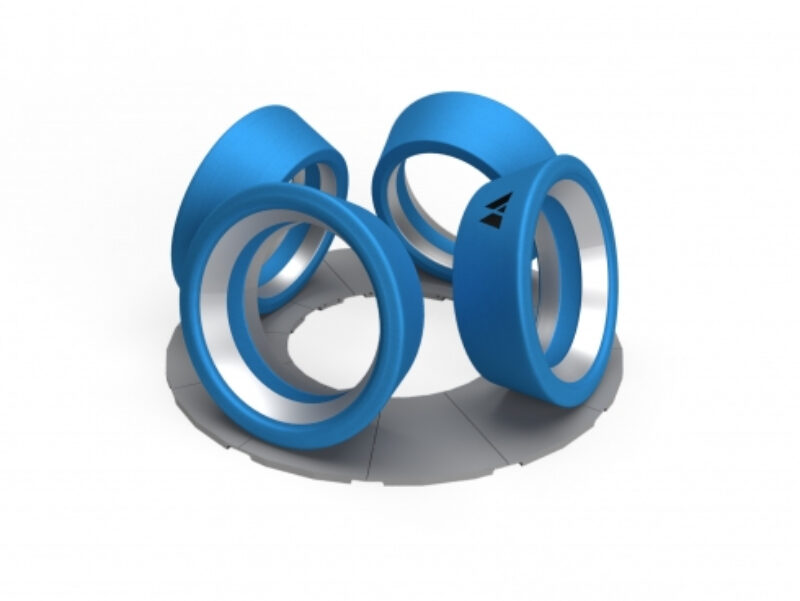

Expand One: A solution exceeding our indonesian customer’s expectations

For years, a cement plant in Indonesia has experienced very rapid wear in its vertical mills.

Background

For years, a cement plant in Indonesia has experienced very rapid wear in its vertical mills. The mills are used for grinding hard limestone (41%), iron sand (34%), silica (24%) and clay (1%). The customer was facing high wear of its rollers and table segments compared to other plants within its group, which was affecting its annual maintenance costs and workers’ safety conditions. The customer had tried other Metal Matrix Composite (MMC) solutions from competitors prior to working with Magotteaux but it did not meet its expectations. The customer turned to Magotteaux to improve the lifetime of its wear parts, save on its annual budget and improve safety.

Solution

Expand One longer-lasting VRM wear parts was THE solution for our customer. A first set of Expand One rollers was installed in October 2021. Our new product has shown outstanding results in harsh operating conditions, and it proved to be the best solution to the customer‘s challenges.

Results

Expand One exceeded the customer’s expectations as it will double the lifetime of the rollers comparing to other ceramic solutions available on the market. Customer has now to shutdown and replace the castings of this mill only once a year during annual outage instead of 2 times per year. The plant was fully satisfied with Expand One and placed a new order in September 2022 for 6 sets of new rollers and 1 set of tables.