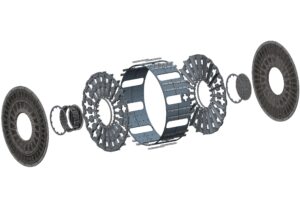

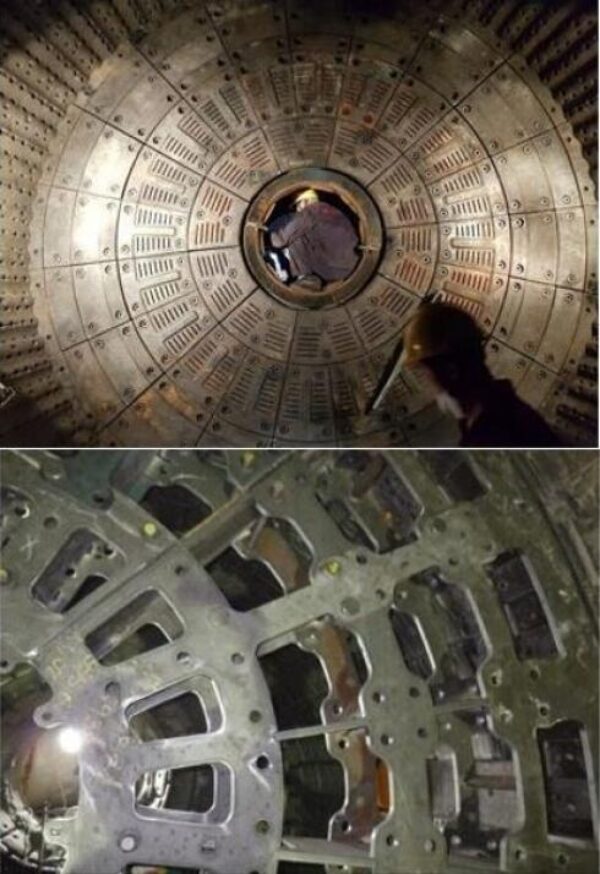

Discharge diaphragms

Whether you operate mono chamber, a two chambers or a double rotator mill with peripheral discharge, our different versions of Magotteaux cement discharge diaphragms can be used with the Magotteaux cement transfer diaphragm and both together make a coherent set of diaphragms.

It is adaptable to any quantity and dimension of the discharge openings in the mill shell.

- Optimization of the grinding process

- Reduced pressure drop due to the large opening area of the center

- Reduced frame wear due to minimal pressure drop

- Full protection of the mill outlet head

- Optimal air and material flows

- Reduced maintenance operations