Perfomance for hard rock dredging

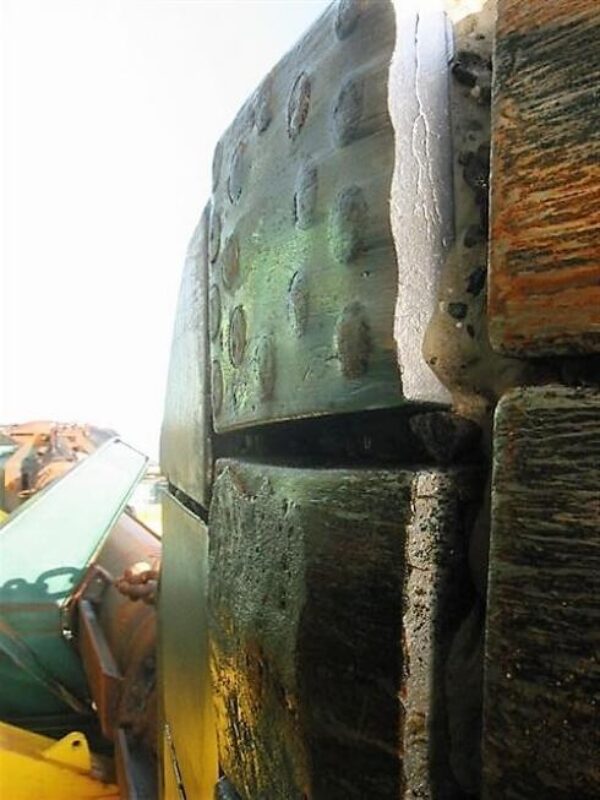

Magotteaux develops and manufactures cutter teeth in high wear resistance cast alloys (including composites) capable to resist the highly abrasive seabed material.

As dredgers are being built with more powerful cutters, Magotteaux increased the resistance of its cutter teeth in order to excavate harder rock without blasting.

Magotteaux developed a specific teeth design and manufactures it in its unique composite material.

- Design: self sharpening of the tooth, better ground penetration, increased production

- Increased lifetime (x 3) -> decreased frequency and duration of maintenance stops, more m3 dredged per day…

- Less power on winches for same m³

- Reduced mechanical stress on the ladder

- Reduced CO2 emission per m³ dredged

- Higher dredger availability