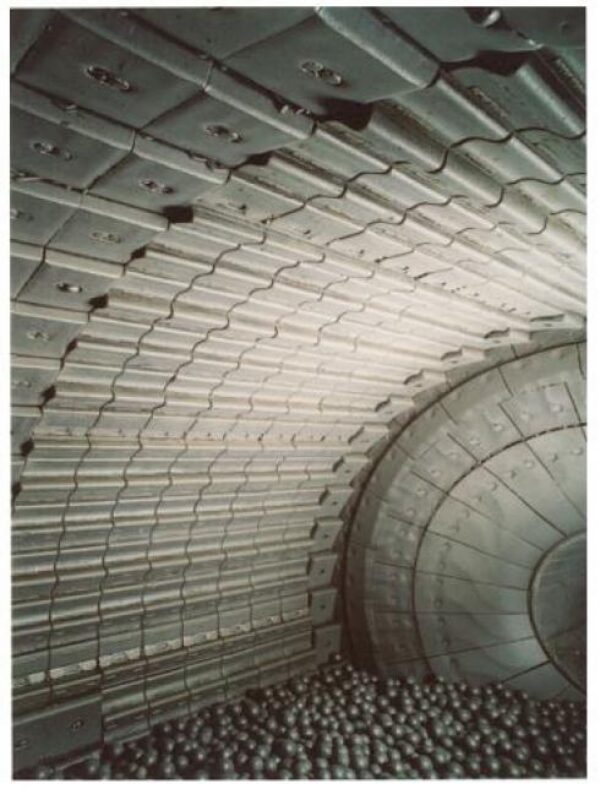

The modular lifting liner

Xlift® is a patented modular lifting liner system consisting of 3 light & interchangeable base plates.

- Reduced liner weight (7-20% vs a traditional bolted step liner), the weight reduction is even higher when compared to vaulted/boltless liner systems

- Eased handling and increased safety thanks to lighter plates

- Shorter maintenance intervention -> Reduced operating costs

- Liner profile layout adapted to mill operating parameters for an optimized grinding efficiency