Milling efficiency optimization

By using the experience of our process engineers, our database (covering >80% of the mines worldwide) and our complete range of tools (laboratory mills for SAG, secondary and ultrafine, pilot plants, modelling etc.), Magotteaux will help improving your milling efficiency.

The parameters impacting milling efficiency

- Ball type, size, density

- Grinding circuit parameters

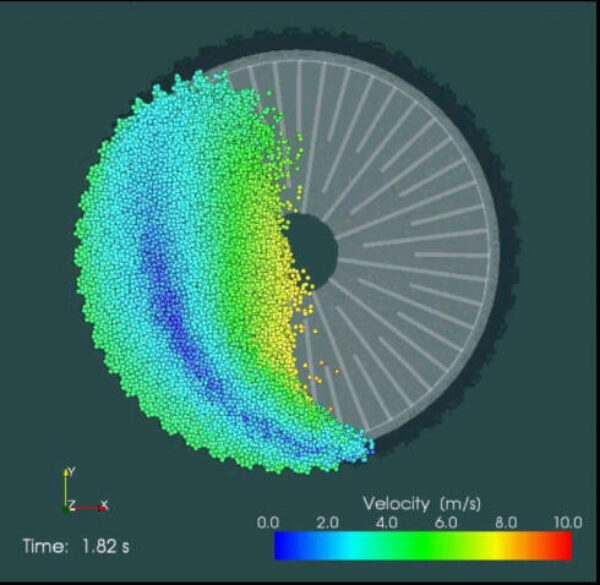

- Mill internals (liner profile, length, filling degree etc.)

- Mill operating parameters (velocity, % circulating load, pulp density etc.)

The importance of monitoring the filling degree and pulp density in real time

The secondary ball mills consume around more than 50% of the total energy in the plant, so any optimization in this area, no matter how small, will have a big impact on the overall concentrator costs.