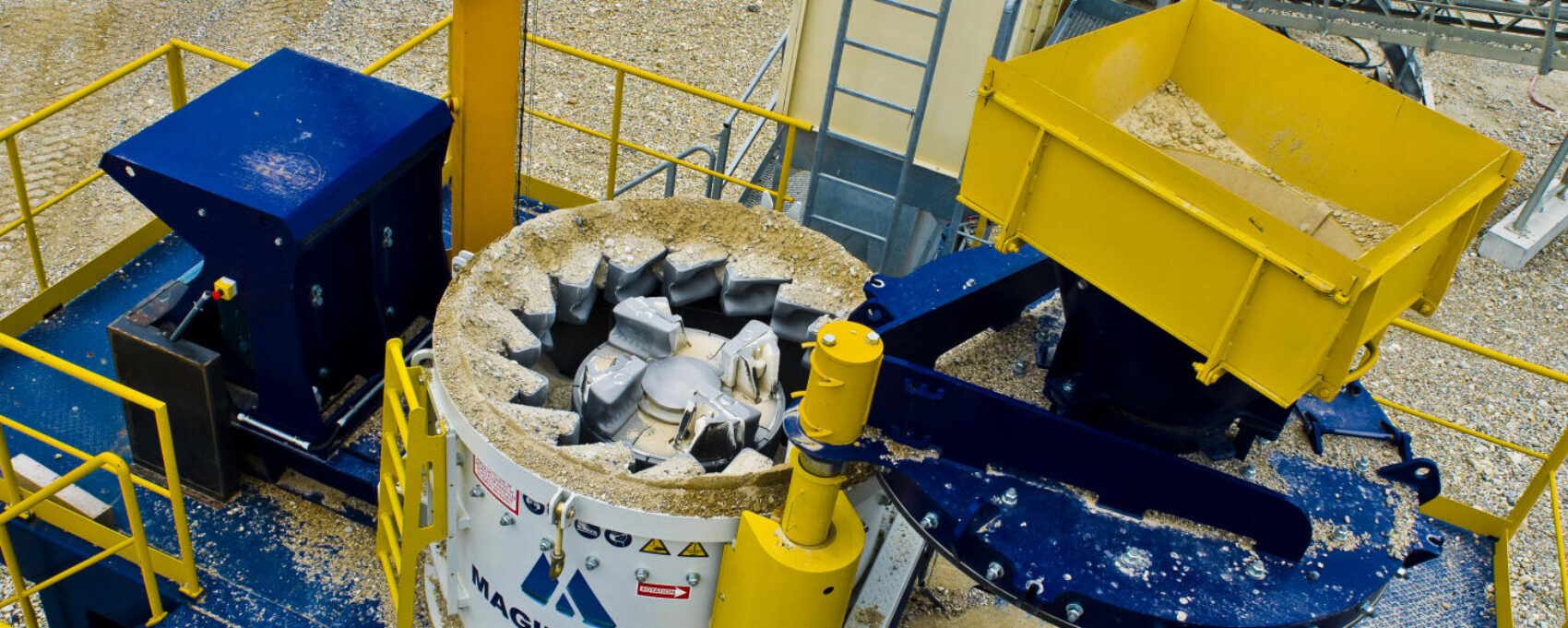

Europe’s only true vertical impactor

Magotteaux offers 3 models of vertical shaft impact crushers Mag’Impact covering most crushing applications thanks to the remarkable flexibility and high capacity of the machine.

The high quality materials produced by our Mag’Impact allow customers to sell aggregates for concrete, asphalt, ballast and special products.

This is possible thanks to the different shapes of anvils and impellers designed to create optimum impact performance.

Mag’Impact main features:

- Constant material output quality

- Simple machine – easy maintenance

- Simplification of the plant’s flow-sheet

- High capacity (up to 500 tph)

- High Performance/Investment ratio