Getting real-time knowledge of what is going on inside your mill

Together with our German partner, KIMA Process Control, we have developed a technological solution, MagoSense, designed specifically for the mining industry. It prevents you running blind by gathering information in order to optimize the working conditions of the mill.

MagoSense presents two major assets:

- All measuring devices are installed directly to the outside of the mill shell. MagoSense does not suffer from sound interference like other off-mill sensors do.

- The energy required to power all the electronics is supplied by a pendulum driven electrical generator. No batteries are necessary.

A new generation tool to improve your production and safety

MagoSense offers you many advantages:

- Maximize mill troughput. MagoSense helps control the mill fill level to avoid mill overloading and allowing better control of mill grind-outs.

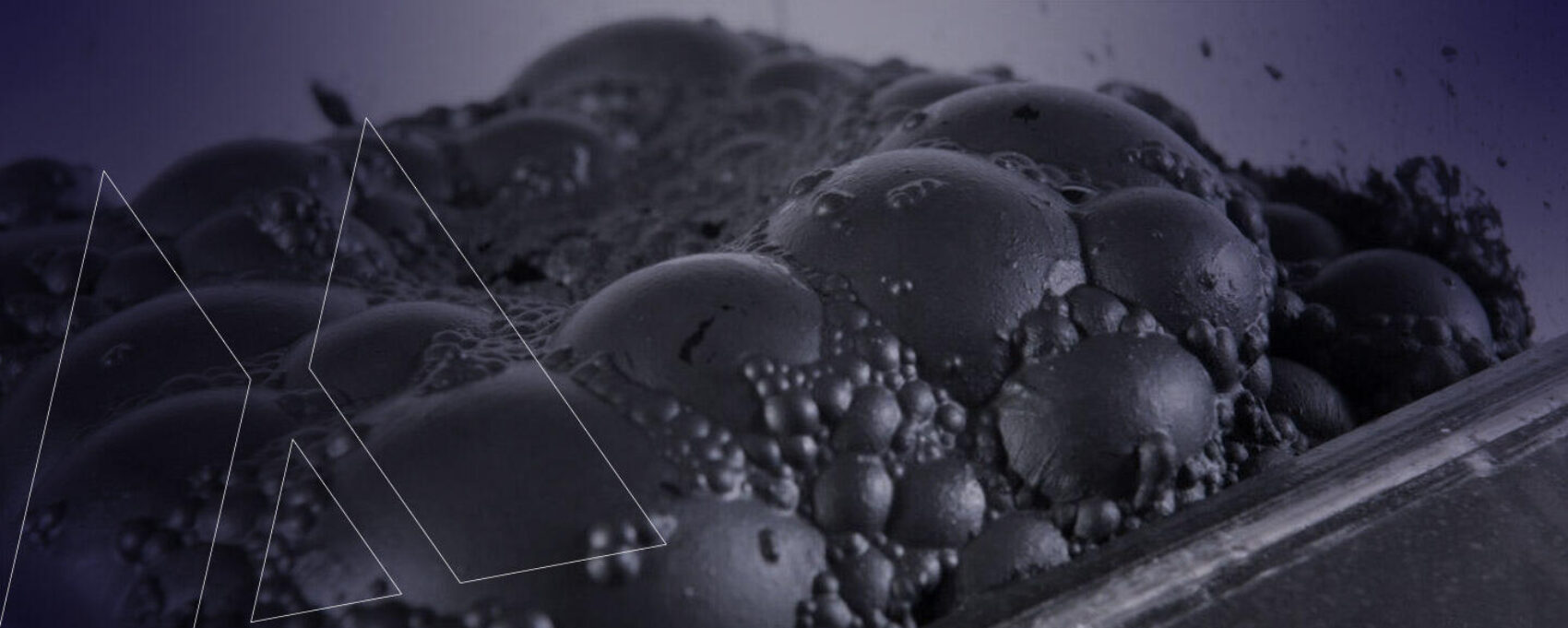

- Minimize liner damage & wear. MagoSense helps reducing the occurrence of ball impacts on liners, thereby extending liner and media lifetime.

- Improve mill efficiency. MagoSense helps the mill operator to decide on the grinding strategy in order to maintain the optimal power and load charge conditions for maximization of the grinding efficiency.

- Reduce mill downtime. MagoSense helps reducing unexpected mill stops due to any type of grinding issue, having a direct positive impact on safety and productivity.