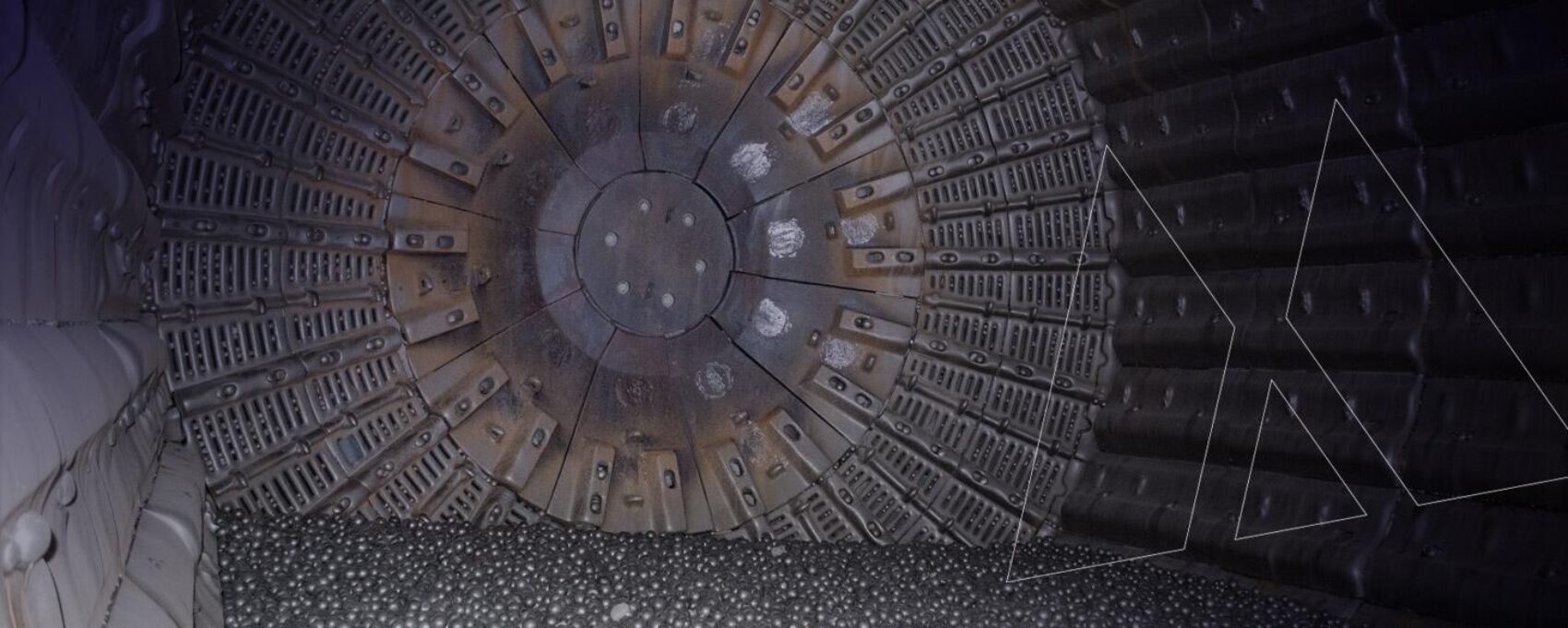

Optimum protection of your mill heads

The role of these liners is to protect the mill heads against wear and offering the longest possible lifetime with the optimal grinding efficiency.

The design will depend on:

- Drilling pattern on mill heads

- Mill speed (rpm)

- Maximum grinding media diameter (mm)

- Grinding media filling degree (%)

Key benefits:

- Optimum compromise between lifetime and grinding efficiency

- Continuous optimization of the liner profile via wear profile studies

- Ease of installation process (filler ring and handling system)

- Anti-pulp racing design to avoid pulp circulation

- Design to minimize the number of plate/liner models

- Design to minimize grinding media consumption