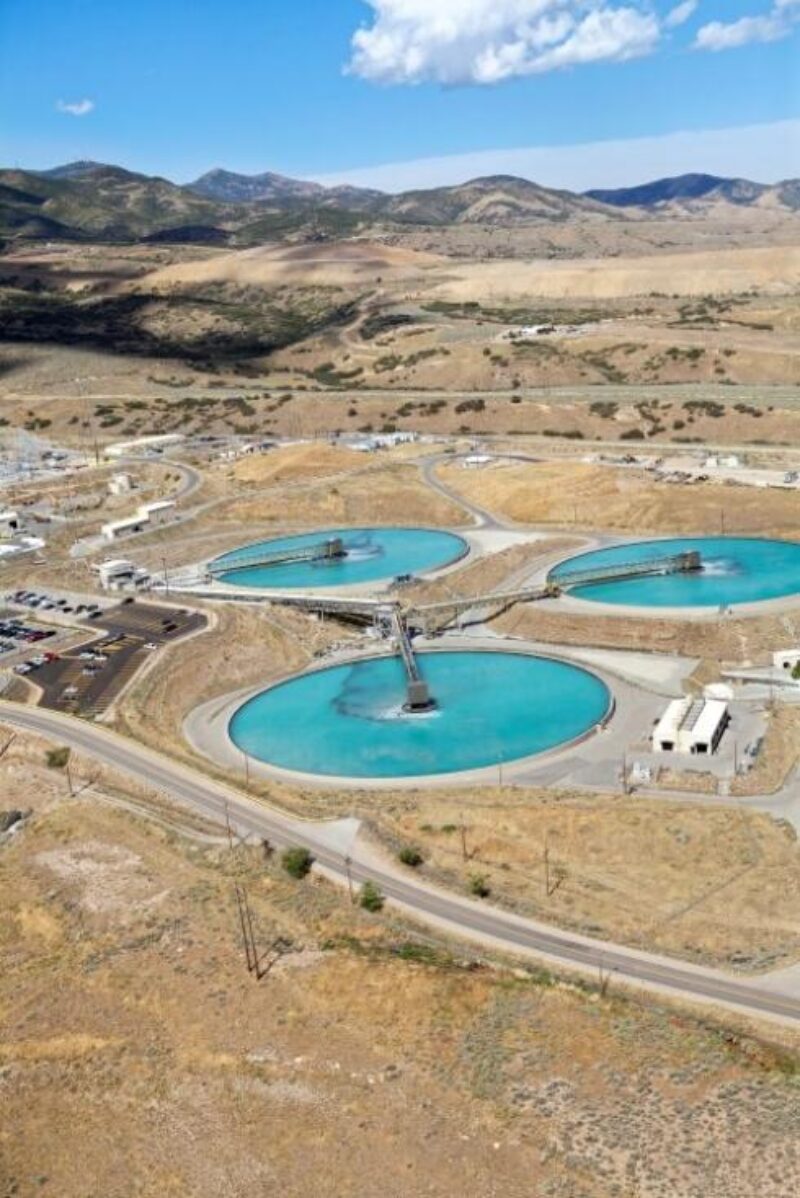

Minería de cobre – Recuperación garantizada

Nuestro cliente estaba examinando formas de reducir sus costos operativos y se acercó a Magotteaux para determinar si se podía usar una bola de cromo secundaria en su molino de bolas para reducir los costos de los cuerpos moledores.

Requerimiento del cliente

Investigar el efecto de la optimización de la aleación en la recuperación de cobre.

Proposito

Se presentó y acordó una propuesta para reducir el contenido de cromo de los cuerpos de molienda. El ahorro de costos esperado fue de $ 200.000 por año. El cliente indicó que, si la planta sufriera una pérdida en la recuperación de cobre, volvería al contenido de cromo inicial de los cuerpos de molienda.

Monitoreo

La química de la pulpa se controló de forma continua durante la purga con PCM®.

Los datos químicos de la pulpa recolectados se examinaron cada quince días para determinar si hubo cambios en la química y si estos cambios en la química tuvieron un efecto adverso en la recuperación del cobre.

El análisis mostró claramente que la recuperación de cobre había disminuido en al menos 1.3% con el cambio de los cuerpos de molienda.Esto representó una pérdida bruta de ingresos de $ 9.0 millones de dólares por año.

Resultado

Solución de Magotteaux: definir la aleación para estabilizar las recuperaciones.

Estas conclusiones se presentaron a nuestro cliente y ellos inmediatamente solicitaron a Magotteaux que suministrara los cuerpos de molienda originales con el mayor contenido de cromo.